Before COVID-19, truck scale intercom systems were already challenging, but now the virus added a new problem. Ever since COVID-19 became a household word, people have become much more sensitive to touching things in public, and likely will long after the virus is under control.

Unfortunately, many truck scale intercoms required truck drivers to pick up a handset to call the scale house operator. There are few things that drivers (or anyone else) want to do less now than put a virus-laden handset up to their mouth and ear. Even just pressing a button to make a call has become less desirable on any type of intercom system.

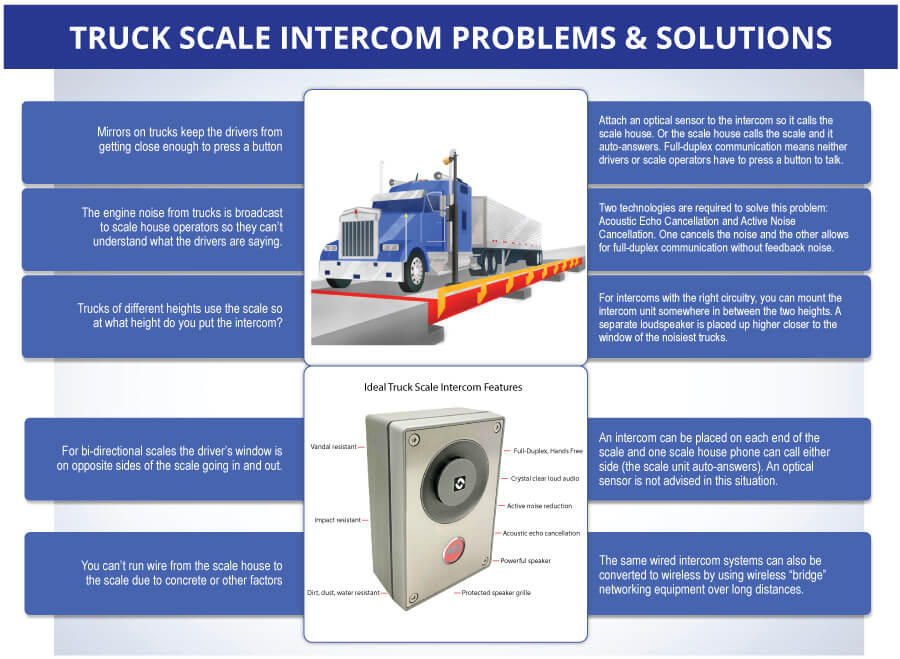

Before COVID-19 there were two main problems to be solved for a truck scale intercom system:

1. The truck scale intercom needs lots of volume to overcome engine noise.

2. The trucks are very loud so scale operators cannot understand the drivers.

It’s easy enough to amplify sound so the driver can hear, and this type of system is the most likely to be installed to the dismay of the scale house personnel who complain about the noise transmitted from the trucks. The hard part of a truck scale is the scale operator side. Two technologies are required to solve the noise problem there: Acoustic Echo Cancellation (AEC) and Active Noise Cancellation (ANC).

These technologies are required since scale intercoms need to be full duplex, which means they can be handsfree on both sides. Drivers have a hard time reaching an intercom past their mirrors and most scale operators are too busy to mess with holding a button down. Plus, drivers do not want to touch a button either.

Acoustic Echo Cancellation is required for full duplex and is used to cancel feedback (squealing noise) on both sides of the system. The higher the volume, the harder AEC must work. It takes processing power and complex, patented software algorithms to make this happen. Now add ANC noise cancellation to cancel out the engine noise and it takes even more processing power. You need systems with quality components and engineering to give you both volume and understandable conversation.

Says Tim Bruxvoort, President of IntercomsOnline.com, “We’ve been through a lot of painful trial and error trying to find systems that work for this challenging application. If you choose the wrong system, which is almost everything on the market, then you’ll either be listening to complaints from your scale operator, or from the drivers. We frequently get calls from people who installed a new system only to have to scrap it and let us change to one that has been battle tested.”

Another factor to consider is how the scale intercom is activated. If scale operators see trucks pull up, they can simply press a button on a phone to call the scale. The scale auto-answers so the driver does nothing, which means they don’t have to touch anything. If scale operators don’t know a truck is there, an optical sensor can be attached to the scale call box so it automatically calls the scale phone. Operators then simply pick up the call.

Scale operators have three ways to talk to drivers. Via a phone handset for noisy scale house applications, by handsfree speakerphone, or using a wired or wireless headset.

Understanding these basic requirements of a truck scale intercom system can save you from making the costly mistake of choosing the wrong system, not to mention having to endure complaints of unsatisfied users. If you want more information on truck scale intercoms you can visit the website at www.intercomsonline.com/truck